| |

| |

Caption: Book - Research on Campus (1949)

This is a reduced-resolution page image for fast online browsing.

EXTRACTED TEXT FROM PAGE:

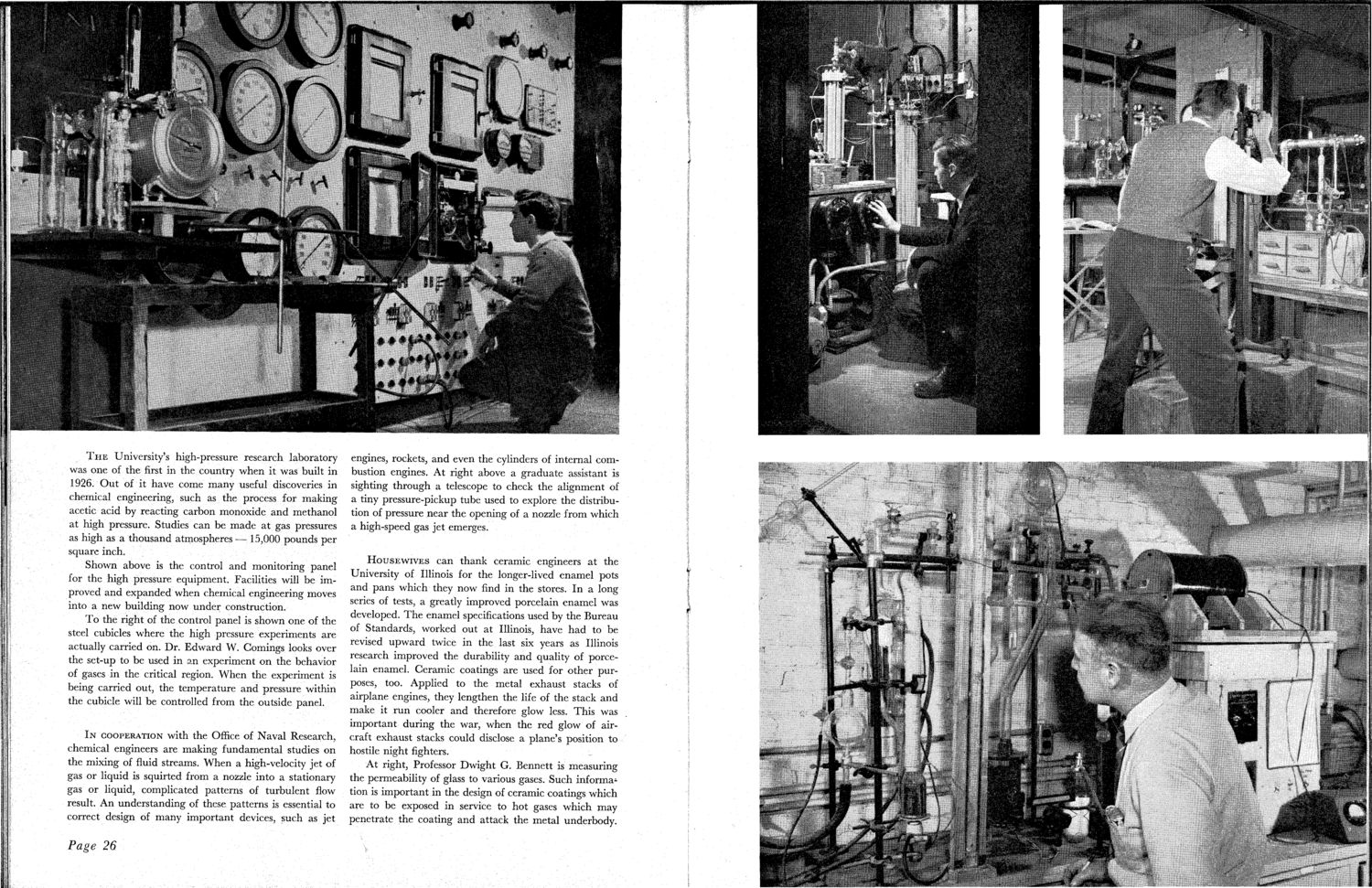

T H E University's high-pressure research laboratory was one of the first in the country when it was built in 1926. O u t of it have come many useful discoveries in chemical engineering, such as the process for making acetic acid by reacting carbon monoxide and methanol at high pressure. Studies can be made at gas pressures as high as a thousand atmospheres — 15,000 pounds per square inch. Shown above is the control and monitoring panel for the high pressure equipment. Facilities will be improved and expanded when chemical engineering moves into a new building now under construction. T o the right of the control panel is shown one of the steel cubicles where the high pressure experiments are actually carried on. Dr. Edward W. Comings looks over the set-up to be used in an experiment on the behavior of gases in the critical region. When the experiment is being carried out, the temperature and pressure within the cubicle will be controlled from the outside panel. I N COOPERATION with the Office of Naval Research, chemical engineers are making fundamental studies on the mixing of fluid streams. When a high-velocity jet of gas or liquid is squirted from a nozzle into a stationary gas or liquid, complicated patterns of turbulent flow result. An understanding of these patterns is essential to correct design of many important devices, such as jet engines, rockets, and even the cylinders of internal combustion engines. At right above a graduate assistant is sighting through a telescope to check the alignment of a tiny pressure-pickup tube used to explore the distribution of pressure near the opening of a nozzle from which a high-speed gas jet emerges. HOUSEWIVES can thank ceramic engineers at the University of Illinois for the longer-lived enamel pots and pans which they now find in the stores. I n a long series of tests, a greatly improved porcelain enamel was developed. T h e enamel specifications used by the Bureau of Standards, worked out at Illinois, have had to be revised upward twice in the last six years as Illinois research improved the durability and quality of porcelain enamel. Ceramic coatings are used for other purposes, too. Applied to the metal exhaust stacks of airplane engines, they lengthen the life of the stack and make it run cooler and therefore glow less. This was important during the war, when the red glow of aircraft exhaust stacks could disclose a plane's position to hostile night fighters. . At right, Professor Dwight G. Bennett is measuring the permeability of glass to various gases. Such information is important in the design of ceramic coatings which are to be exposed in service to hot gases which may penetrate the coating and attack the metal underbody. Page 26

| |