Caption: Board of Trustees Minutes - 1886

This is a reduced-resolution page image for fast online browsing.

EXTRACTED TEXT FROM PAGE:

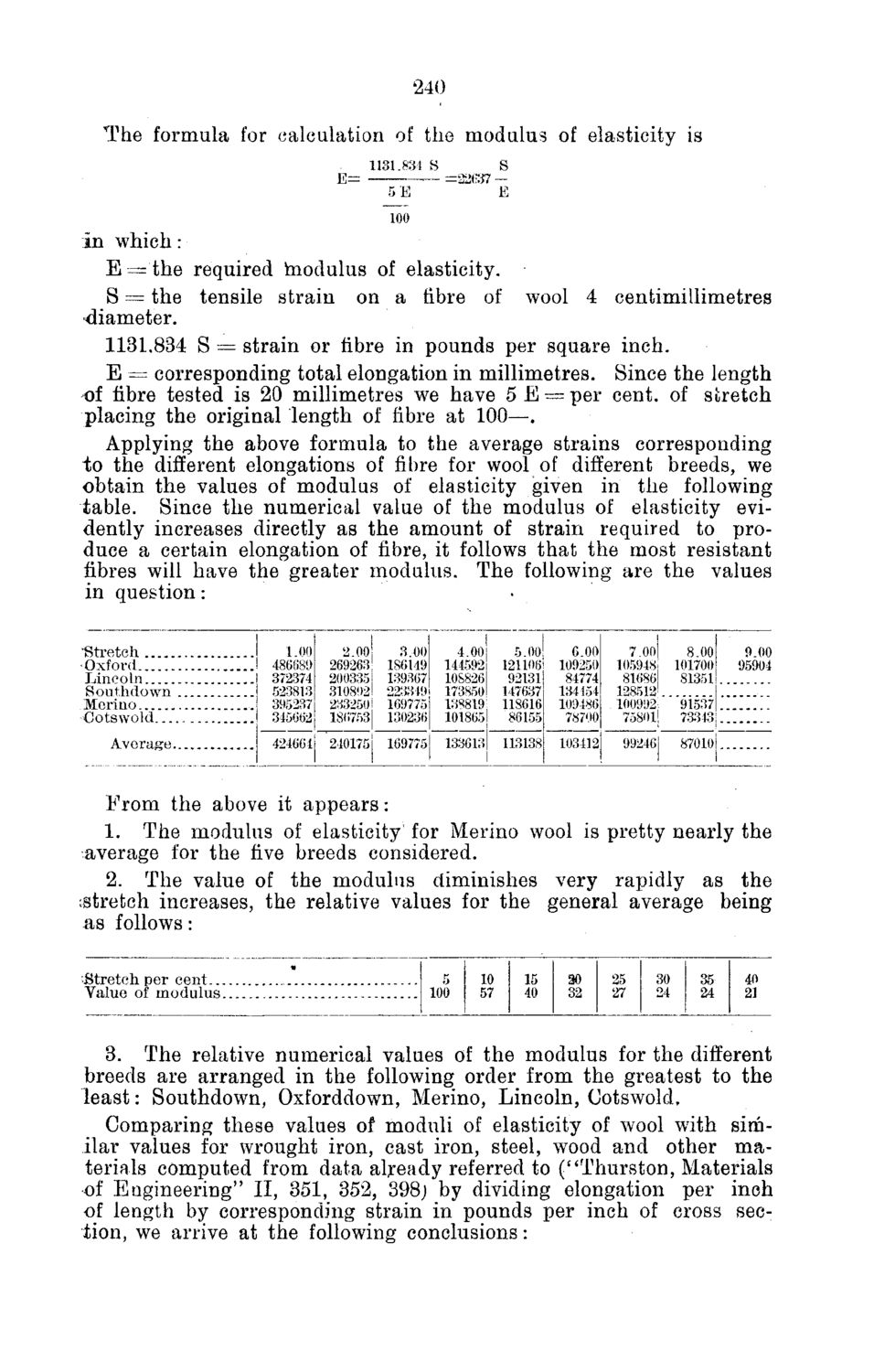

240 The formula for calculation of the modulus of elasticity is E - 1131.834 S S . _ _ -22637 5E 100 E In which: E = the required rnodulus of elasticity. S = the tensile strain on a fibre of wool 4 centimillimetres diameter. 1131.834 S = strain or fibre in pounds per square inch. E — corresponding total elongation in millimetres. Since the length of fibre tested is 20 millimetres we have 5 E — per cent, of stretch placing the original length of fibre at 100—. Applying the above formula to the average strains corresponding io the different elongations of fibre for wool of different breeds, we obtain the values of modulus of elasticity given in the following table. Since the numerical value of the modulus of elasticity evidently increases directly as the amount of strain required to produce a certain elongation of fibre, it follows that the most resistant fibres will have the greater modulus. The following are the values in question: • •Stretch Oxford Lincoln Southdown Cotswold Average 1.00 486689 372374 523813 345662 424664 240175 3.00 1S6149 139367 223349 169775 130236 169775 4.00 144592 10S826 173850 138819 101865 133613 5.00 121106 92131 147637 118616 86155 113138 6.00 109250 84774 134154 109486 78700 103412 7.00 105948 81686 128512 100992 75801 99246 8.00 101700 81351 91537 87010 9.00 95904 From the above it appears: 1. The modulus of elasticity for Merino wool is pretty nearly the average for the five breeds considered. 2. The value of the modulus diminishes very rapidly as the stretch increases, the relative values for the general average being as follows: •Stretch p e r c e n t Value of m o d u l u s 5 100 10 57 15 40 20 32 25 27 30 24 35 24 40 21 3. The relative numerical values of the modulus for the different breeds are arranged in the following order from the greatest to the least: Southdown, Oxforddown, Merino, Lincoln, Cotswold, Comparing these values of moduli of elasticity of wool with similar values for wrought iron, cast iron, steel, wood and other materials computed from data already referred to ("Thurston, Materials of Engineering" II, 351, 352, 398j by dividing elongation per inch of length by corresponding strain in pounds per inch of cross section, we arrive at the following conclusions:

|