Caption: Dedication - New Chemistry Building

This is a reduced-resolution page image for fast online browsing.

EXTRACTED TEXT FROM PAGE:

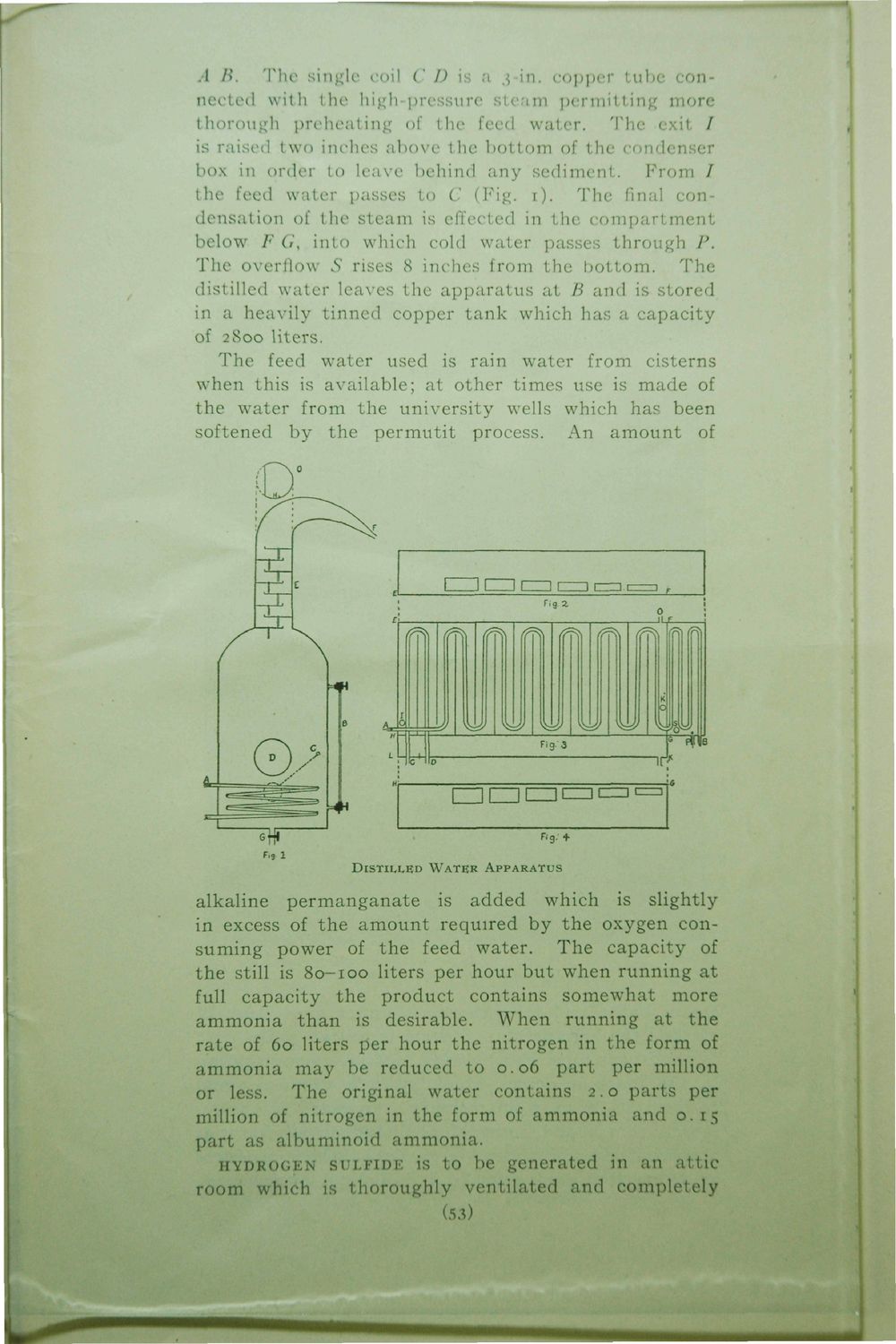

A B. The single coil C D is a 3-in. copper tube connected with the high-pressure steam permitting more thorough preheating of the feed water. The exit I is raised two inches above the bottom of the condenser box in order to leave behind any sediment. Prom / the feed water passes to C (Fig. i ) . The final condensation of the steam is effected in the compartment below F Gy into which cold water passes through P. The overflow S rises 8 inches from the bottom. The distilled water leaves the apparatus at B and is stored in a heavily tinned copper tank which has a capacity of 2800 liters. The feed water used is rain water from cisterns when this is available; at other times use is made of the water from the university wells which has been softened by the permutit process. An amount of [ 11 11 11—11=). <n =* ^ ^ ^ ^ ^ 0, ^ lL ^ ^ rig.'3 ^ ife ] • • ! = ] C=l *3.' + DISTILLED W A T E R APPARATUS alkaline permanganate is added which is slightly in excess of the amount required by the oxygen consuming power of the feed water. The capacity of the still is 80-100 liters per hour but when running at full capacity the product contains somewhat more ammonia t h a n is desirable. When running at the rate of 60 liters per hour the nitrogen in the form of ammonia may be reduced to 0.06 part per million or less. The original water contains 2.0 parts per million of nitrogen in the form of ammonia and o. 15 part as albuminoid ammonia. HYDROGEN SULFIDE is to be generated in an attic room which is thoroughly ventilated and completely (53)

|