| |

| |

Caption: Course Catalog - 1875-1876

This is a reduced-resolution page image for fast online browsing.

EXTRACTED TEXT FROM PAGE:

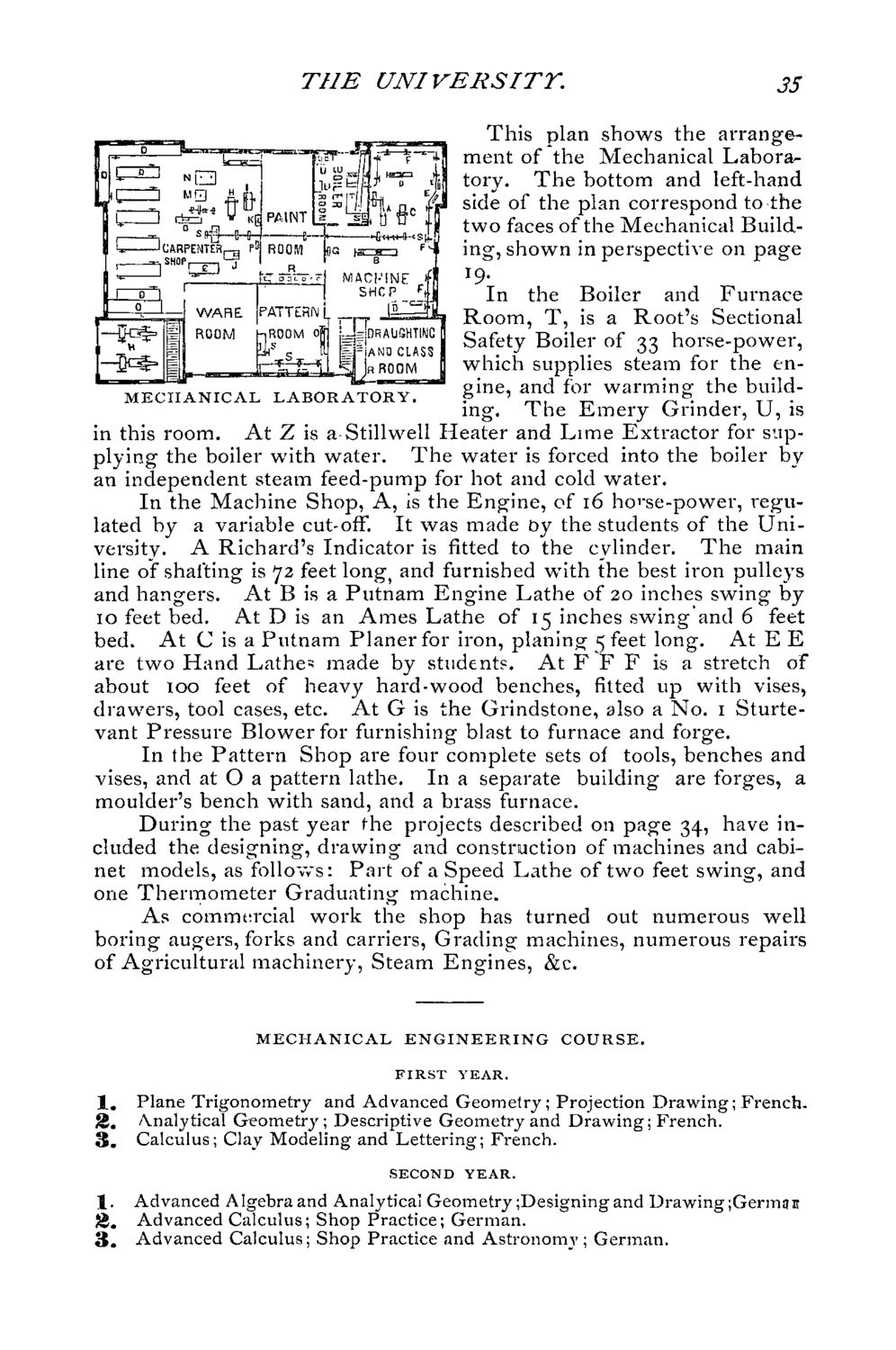

THE UNIVERSITY. 35 This plan shows the arrangement of the Mechanical Laboratory. The bottom and left-hand side of the plan correspond to the two faces of the Mechanical Building, shown in perspective on page 19. In the Boiler and Fui"nace Room, T, is a Root's Sectional Safety Boiler of 33 horse-power, which supplies steam for the engine, and for warming the buildMECHANICAL LABORATORY. ing. The Emery Grinder, U, is in this room. At Z is a-Stillwell Heater and Lime Extractor for supplying the boiler with water. The water is forced into the boiler by an independent steam feed-pump for hot and cold water. In the Machine Shop, A, is the Engine, of 16 horse-power, regulated by a variable cut-off. It was made by the students of the University. A Richard's Indicator is fitted to the cylinder. The main line of shafting is 72 feet long) and furnished with the best iron pulleys and hangers. At B is a Putnam Engine Lathe of 20 inches swing by 10 feet bed. At D is an Ames Lathe of 15 inches swing and 6 feet bed. At C is a Putnam Planer for iron, planing ^ feet long. At E E are two Hand Lathe* made by students. At F F F is a stretch of about 100 feet of heavy hard-wood benches, fitted up with vises, drawers, tool cases, etc. At G is the Grindstone, also a No. 1 Sturtevant Pressure Blower for furnishing blast to furnace and forge. In the Pattern Shop are four complete sets of tools, benches and vises, and at O a pattern lathe. In a separate building are forges, a moulder's bench with sand, and a brass furnace. During the past year the projects described on page 34, have included the designing, drawing and construction of machines and cabinet models, as follows: Part of a Speed Lathe of two feet swing, and one Thermometer Graduating machine. As commercial work the shop has turned out numerous well boring augers, forks and carriers, Grading machines, numerous repairs of Agricultural machinery, Steam Engines, &c. MECHANICAL ENGINEERING COURSE. FIRST YEAR. 1 . Plane Trigonometry and Advanced Geometry; Projection Drawing; French3 . Analytical Geometry; Descriptive Geometry and Drawing; French. 3 . Calculus; Clay Modeling and Lettering; French. SECOND YEAR. 1. Advanced Algebra and Analytical Geometry ;Designing and Drawing [German S . Advanced Calculus; Shop Practice; German. 3 . Advanced Calculus; Shop Practice and Astronomy; German.

| |