| |

| |

Caption: Board of Trustees Minutes - 1880

This is a reduced-resolution page image for fast online browsing.

EXTRACTED TEXT FROM PAGE:

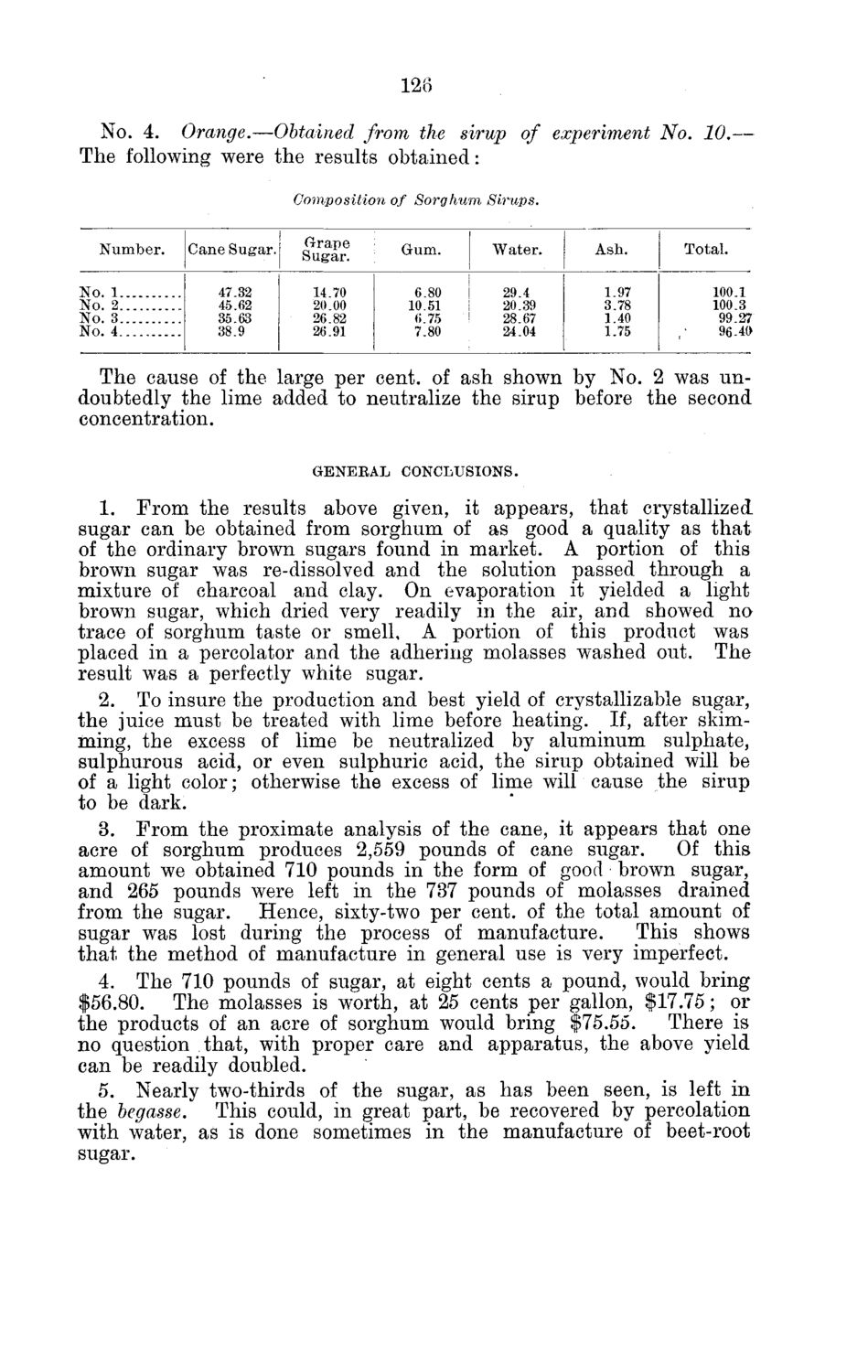

126 No. 4. Orange.—Obtained from the sirup of experiment No. 10.— The following were the results obtained: Composition Number. No. No. No. No. 1 2 3 4 Cane Sugar. 47.32 45.62 35.63 38.9 Grape Sugar. 14.70 20.00 26.82 26.91 of Sorghum Gum. 6.80 10.51 6.75 7.80 Sirups. Water. 29.4 20.39 28.67 24.04 Ash. 1.97 3.78 1.40 1.75 Total. 100.1 100.3 99.27 96-40 The cause of the large per cent, of ash shown by No. 2 was undoubtedly the lime added to neutralize the sirup before the second concentration. GENEKAL CONCLUSIONS. 1. From the results above given, it appears, that crystallized sugar can be obtained from sorghum of as good a quality as that of the ordinary brown sugars found in market. A portion of this brown sugar was re-dissolved and the solution passed through a mixture of charcoal and clay. On evaporation it yielded a light brown sugar, which dried very readily in the air, and showed no trace of sorghum taste or smell, A portion of this product was placed in a percolator and the adhering molasses washed out. The result was a perfectly white sugar. 2. To insure the production and best yield of crystallizable sugar, the juice must be treated with lime before heating. If, after skimming, the excess of lime be neutralized by aluminum sulphate, sulphurous acid, or even sulphuric acid, the sirup obtained will be of a light color; otherwise the excess of lime will cause the sirup to be dark. 3. From the proximate analysis of the cane, it appears that one acre of sorghum produces 2,559 pounds of cane sugar. Of this amount we obtained 710 pounds in the form of good brown sugar, and 265 pounds were left in the 737 pounds of molasses drained from the sugar. Hence, sixty-two per cent, of the total amount of sugar was lost during the process of manufacture. This shows that the method of manufacture in general use is very imperfect. 4. The 710 pounds of sugar, at eight cents a pound, would bring $56.80. The molasses is worth, at 25 cents per gallon, $17.75; or the products of an acre of sorghum would bring $75.55. There is no question that, with proper care and apparatus, the above yield can be readily doubled. 5. Nearly two-thirds of the sugar, as has been seen, is left in the begasse. This could, in great part, be recovered by percolation with water, as is done sometimes in the manufacture of beet-root sugar.

| |