| |

| |

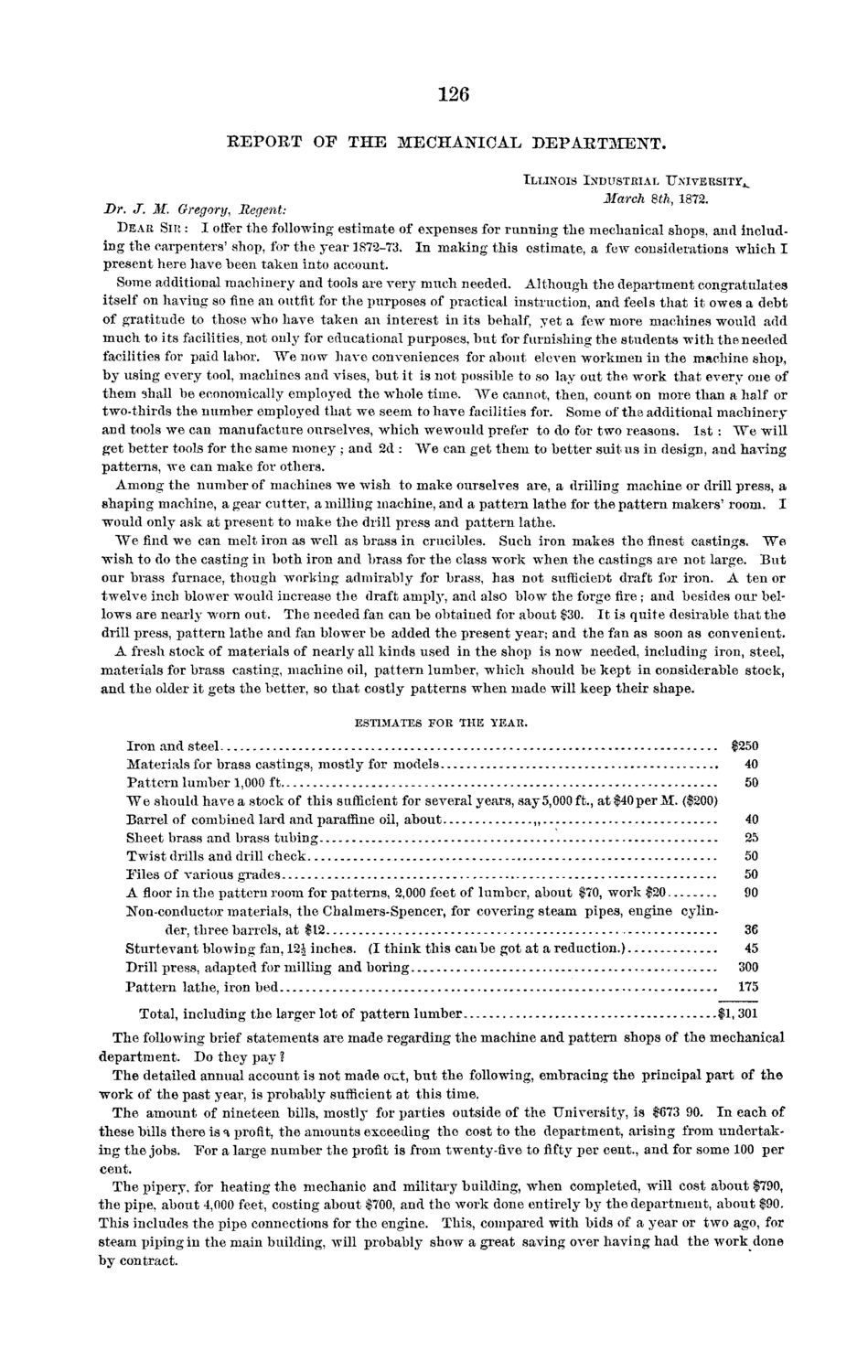

Caption: Board of Trustees Minutes - 1872

This is a reduced-resolution page image for fast online browsing.

EXTRACTED TEXT FROM PAGE:

126 REPORT OF THE MECHANICAL DEPARTMENT. ILLINOIS INDUSTRIAL UNIVERSITY^ ^ r March 8th, 1872. Dr. J. M. Gregory, Regent: DEAR SIR : I offer the following estimate of expenses for running the mechanical shops, and including the carpenters' shop, for the year 1872-73. In making this estimate, a few considerations which I present here have been taken into account. Some additional machinery and tools are very much needed. Although the department congratulates itself on having so fine an outfit for the purposes of practical instruction, and feels that it owes a debt of gratitude to those who have taken an interest in its behalf, yet a few more machines would add much to its facilities, not only for educational purposes, but for furnishing the students with the needed facilities for paid labor. We now have conveniences for about eleven workmen in the machine shop, by using every tool, machines and vises, but it is not possible to so lay out the work that every one of them shall be economically employed the whole time. We cannot, then, count on more than a half or two-thirds the number employed that we seem to have facilities for. Some of the additional machinery and tools we can manufacture ourselves, which wewould prefer to do for two reasons. 1st : We will get better tools for the same money ; and 2d : We can get them to better suit us in design, and having patterns, we can make for others. Among the number of machines we wish to make ourselves are, a drilling machine or drill press, a shaping machine, a gear cutter, a milling machine, and a pattern lathe for the pattern makers' room. I would only ask at present to make the drill press and pattern lathe. We find we can melt iron as well as brass in crucibles. Such iron makes the finest castings. We wish to do the casting in both iron and brass for the class work when the castings are not large. But our brass furnace, though working admirably for brass, has not sufficieDt draft for iron. A ten or twelve inch blower would increase the draft ampty, and also blow the forge fire ; and besides our bellows are nearly worn out. The needed fan can be obtained for about $30. I t is quite desirable that the drill press, pattern lathe and fan blower be added the present year; and the fan as soon as convenient. A fresh stock of materials of nearly all kinds used in the shop is now needed, including iron, steel, materials for brass casting, machine oil, pattern lumber, which should be kept in considerable stock, and the older it gets the better, so that costly patterns when made will keep their shape. ESTIMATES FOR T H E YEAR. Iron and steel $250 Materials for brass castings, mostly for models 40 Pattern lumber 1,000 ft 50 We should have a stock of this sufficient for several years, say 5,000 ft, at |40per M. ($200) Barrel of combined lard and paraffine oil, about ,, 40 Sheet brass and brass tubing 25 Twist drills and drill check 50 Piles of various grades 50 A floor in the pattern room for patterns, 2,000 feet of lumber, about $70, work $20 90 Non-conductor materials, the Chalmers-Spencer, for covering steam pipes, engine cylinder, three barrels, at $12 36 Sturtevant blowing fan, 12J inches. (I think this can be got at a reduction.) 45 Drill press, adapted for milling and boring 300 Pattern lathe, iron bed 175 Total, including the larger lot of pattern lumber $1,301 The following brief statements are made regarding the machine and pattern shops of the mechanical department. Do they pay ? The detailed annual account is not made out, but the following, embracing the principal part of the work of the past year, is probably sufficient at this time. The amount of nineteen bills, mostly for parties outside of the University, is $673 90. In each of these bills there is a profit, the amounts exceeding the cost to the department, arising from undertaking the jobs. Por a large number the profit is from twenty-five to fifty per cent., and for some 100 per cent. The pipery, for heating the mechanic and military building, when completed, will cost about $790, the pipe, about 4,000 feet, costing about $700, and the work done entirely by the department, about $90. This includes the pipe connections for the engine. This, compared with bids of a year or two ago, for steam piping in the main building, will probably show a great saving over having had the work done by contract.

| |