Caption: Magazine - Illinois Chemist (1922 Selections)

This is a reduced-resolution page image for fast online browsing.

EXTRACTED TEXT FROM PAGE:

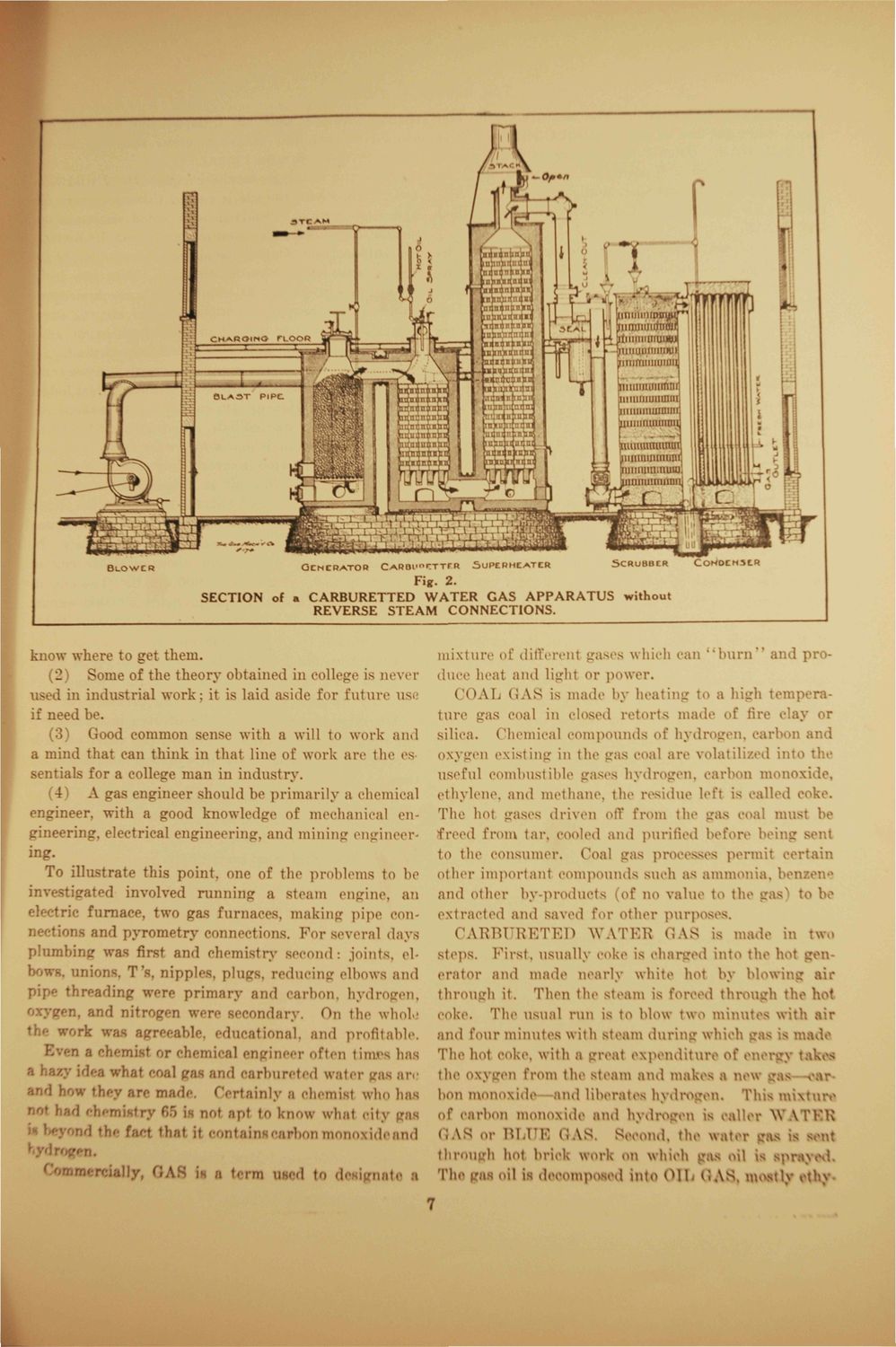

BUOWCR OCNERATOR CARBl'TTTfR SUPERHEATER SCRUBUCR CONDENSER Fig. 2. SECTION of a CARBURETTED WATER GAS APPARATUS without REVERSE STEAM CONNECTIONS. know where to get them. (2) Some of the theory obtained in college is never US d in industrial work: it is laid aside for future us if need be. (3) (iood common sense with a will to work and a mind that can think in that line of work are the es -entials for a college man in industry. (4) A gas engineer should be primarily a chemical engineer, with a good knowledge of mechanical engineering, electrical engineering, and mining engineei ing. To illustrate this point, one of the problems to be investigated involved running a steam engine, an electric furnace, two gas furnaces, making pipe coni. 'ions and pyromctry connections. For several days plumbing was first and chemistry second: joints, elbows, unions. T's. nipp! plugs, reducing elbows and pi: hreading were primary and carbon, hydrogen, en, and nitropen were secondary. On the wholo mixture of differenl gases which can " b u r n " and produce heat and lighl or power. COAL GAS is made by heating to a high temperature <^as coal in closed retorts made of tire clay "r silica. Chemical compounds of hydr n, carbon and xygen existing in the gas coal arc volatilized into th useful combustible gases hydrogen, carbon monoxi ethylene, and methane, the residue left is called eokThe hot gases driven off from the gas coal must be freed from tar, cooled and purified before being sent to the consumer. Coal gas processes permit certain other important compounds such as ammonia, bet me and other by-products yo'i no value to the as] to I extracted and saved for other purpOJ i. CARBURETED WATER GAS is made in two steps. First, usually coke is charged into the hot generator and made nearly white hot by blowing air through it. Then the steam is forced through the 1 coke. The usual run is to blow two minutes with air work was agreeable, educational, and profitable. E n a chemist or chemical engineer often times ha idea what coal ga ind carbureted water gas aru and how they are made. Certainly a chemist who has had chemistry 65 is not apt to know what city g&B and four minutes with steam during which gas lade Tin- hot coke, with a great expenditure of energy tak< s the oxygen from the steam and makes bon monoxide and liberates hydrogen. new us carThis mixtui » b * < dr< i the fa* that it contain i. I carbon monoxide and hydrogen is caller WATKR rbon monoxide and CAS or BLUE GAS. Second, the water gas is sent through hot brick work on which gas oil is sprayed. The gas oil is decomposed into Oil, CAS. mostly othy. Commercially, \ S in a term used to designate a 7

|