| |

| |

Caption: Dedication - Materials Testing Lab Dedication

This is a reduced-resolution page image for fast online browsing.

EXTRACTED TEXT FROM PAGE:

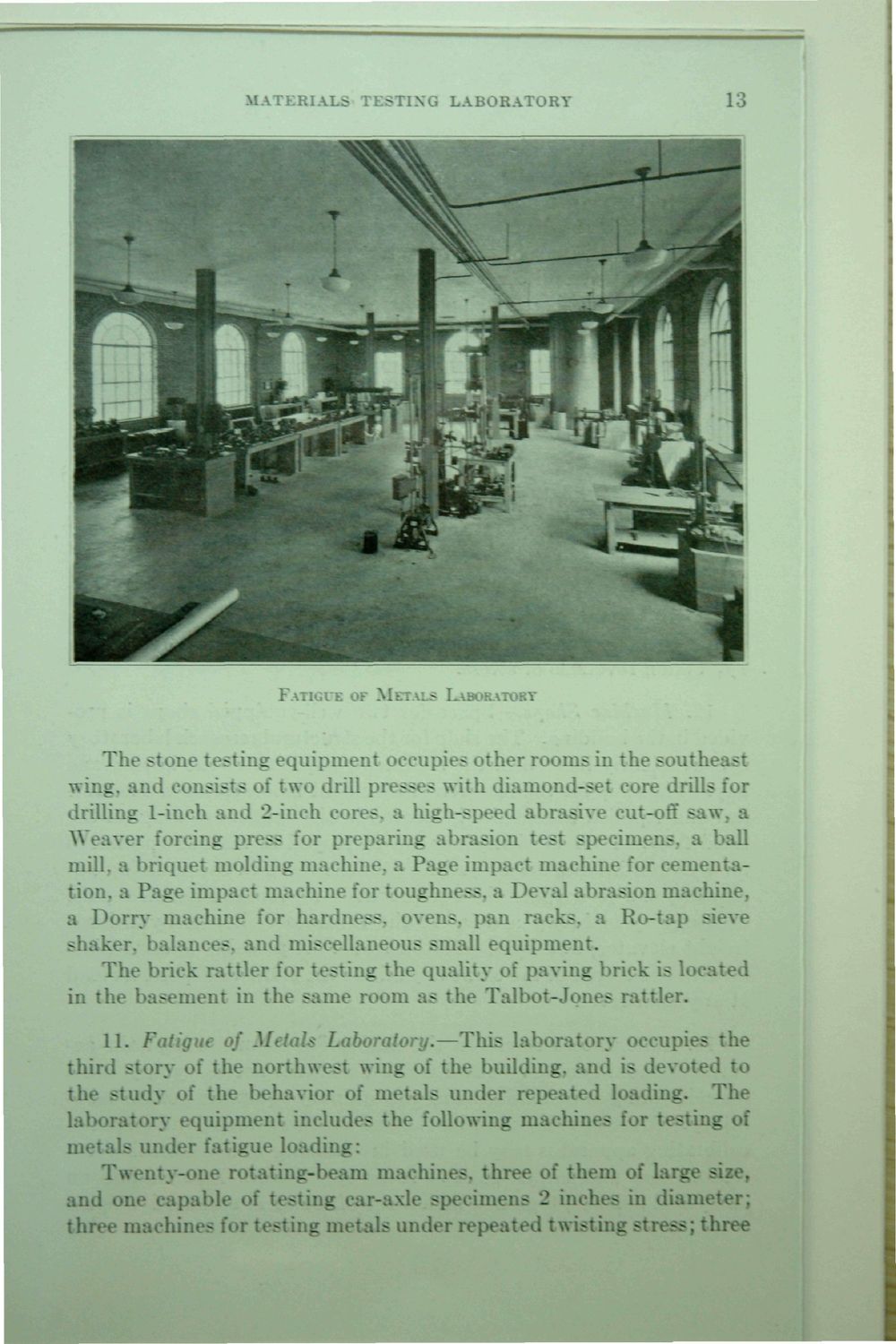

MATERIALS* TESTING LABORATORY 13 FATIGUE OF M E T A L S LABORATORY The stone testing equipment occupies other rooms in the southeast wing, and consists of two drill presses with diamond-set core drills for drilling 1-inch and 2-inch cores, a high-speed abrasive cut-off saw, a Weaver forcing press for preparing abrasion test specimens, a ball mill, a briquet molding machine, a Page impact machine for cementation, a Page impact machine for toughness, a Deval abrasion machine, a Dorry machine for hardness, ovens, pan racks, a Ro-tap sieve shaker, balances, and miscellaneous small equipment. The brick rattler for testing the quality of paving brick is located in the basement in the same room as the Talbot-Jones rattler. 11. Fatigue of MetaU Laboratory.—This laboratory occupies the third story of the northwest wing of the building, and is devoted to the study of the behavior of metals under repeated loading. The laboratory equipment includes the following machines for testing of metals under fatigue loading: Twenty-one rotating-beam machines, three of them of large size, and one capable of testing car-axle specimens 2 inches in diameter; three machines for testing metals under repeated twisting stress; three

| |